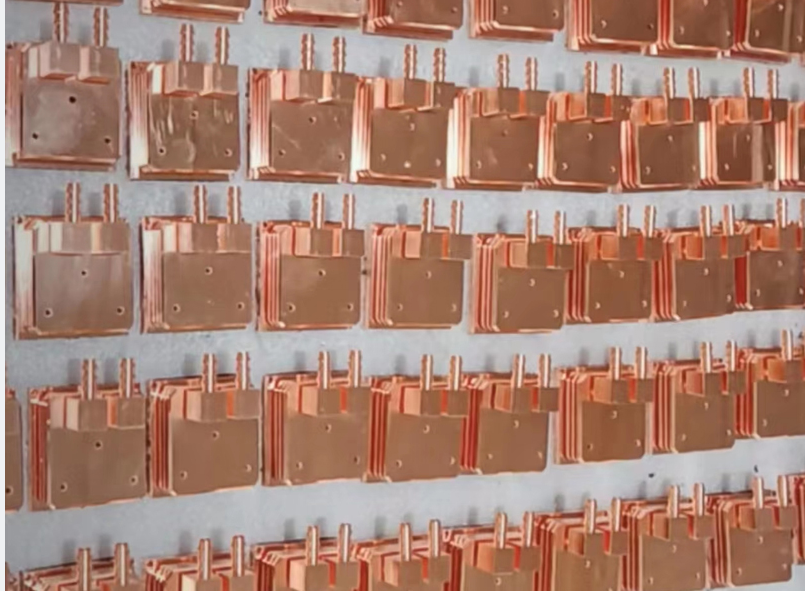

High Precision Machining: Macro channel &Micro Channel Heatsink and Thermal Transfer Heatsink

Thermal management is a crucial aspect in semiconductor lasers. Macro channel heatsink and thermal conduction heatsink, as critical heat dissipation components, require not only ultra-high precision, but also mirror-grade surfaces and perfect critical edge machining. We use high-precision machining equipment, combined with leading-edge process technology capabilities and specialized thermal and runner design to ensure excellent performance and reliability.

Macro Channel Heatsink achieve efficient heat dissipation performance through a larger runner design for high power devices that require rapid heat dissipation.

1.Ultra High Precision Machining

The design of the macro channel heat sink requires precise machining to ensure that the coolant flows through the runners with minimal resistance. Imported high-precision machining equipment is capable of achieving micron-level machining accuracy, ensuring strict control of the size and shape of the flow channel.

2.Mirror Grade Surface

The surface quality of the macro channel heatsink directly affects its heat dissipation effect. Through advanced machining technology, we are able to realize mirror-grade surface finish and reduce the porosity of the thermal interface, thus improving the cooling efficiency.

3.Critical Edge Processing

The edge design of heatsink is critical to their structure and performance. By accurately machining perfect critical edges, we ensure the structural integrity and reliability of heatsink.

Micro Channel Heatsink could achieve better efficient heat dissipation performance through a finer runner than Macro Channel,it specially design for high power devices that require rapid heat dissipation and in a limited space.

Meanwhile , it needs more precision machining and more rich experience.

Microchannel heatsink is a highly efficient heat transfer device. It rapidly transports heat from a heat source to a cooling medium by creating thousands of micro-channels within the micron scale for fast and uniform heat transfer. Microchannel heat sinks are usually made of materials with high thermal conductivity, such as copper, aluminum, titanium, and stainless steel, and can be fabricated through microelectronic processing technology.

Compared with traditional heat sinks, microchannel heat sinks have higher heat transfer efficiency and smaller size. It can be widely used in electronic devices optoelectronic equipment, lasers, battery management systems and other fields, effectively improving the stability and reliability of these devices

However, microchannel heat sink has some problems in the process of use. Due to its tiny size and complex manufacturing process, the manufacturing cost is high. In addition, in extreme environments such as high temperatures and pressures, microchannel heat sinks may become clogged or corroded, which in turn affects their heat transfer performance.

Overall, microchannel heat sink is an efficient thermal management technology worth studying and applying, but it is necessary to continuously improve its manufacturing process and optimize its structural design to meet the practical needs of different fields.

Thermal conduction heatsink utilizes the high thermal conductivity of the material itself to rapidly diffuse the heat to the heat dissipating surface through conduction, and then emit the heat through air convection or other means.

1.Thermal Design Capability

Optimizing the design of heatsink for heat transfer requires sophisticated thermal design capabilities. We have a professional thermal design team that can design the best heatsink structure according to specific application scenarios to maximize heat transfer efficiency.

2.Precision Processing

When processing heatsink for heat transfer, we utilize the precision machining capabilities of imported equipment. This equipment ensures that the dimensions and shapes of each part of the heat sink are perfectly matched to achieve optimal heat transfer performance.

3.Processing mastery

Our team has accumulated a wealth of machining experience and technology, and we are able to master a variety of complex machining processes. Whether it's runner processing for macro channel heatsink or precision milling for heat transfer heatsink, we are able to ensure the quality and performance of each product with our skillful techniques and advanced equipment.

In the heatsink surface treatment of semiconductor lasers, the nickel and gold (Ni/Au) plating process is a key technology, the main purpose of which is to improve the thermal conductivity and corrosion resistance of the heat sink, so as to ensure the stability and long life of the laser. We have advanced Ni/Au plating capability, which can form a uniform and high quality Ni/Au layer on the heat sink surface, with the following advantages:

1. Ultra-high precision plating

Our plating process is capable of achieving micron-level precision, ensuring a uniform thickness of the nickel-gold layer, avoiding any transitions or defects, and providing optimal thermal and electrical conductivity.

2.Excellent thermal conductivity

The nickel-plated layer provides good underlying thermal conductivity, while the gold-plated layer offers excellent thermal conductivity and oxidation resistance. Combining the advantages of these two materials can significantly improve the overall thermal efficiency of heat sinks.

3.Enhanced corrosion resistance

The gold-plated layer has strong corrosion resistance, which can effectively prevent the erosion of environmental factors on the heat sink, thus extending the service life of the semiconductor laser.

4.Mirror-grade surface treatment

Through precise control of plating parameters, we are able to achieve a mirror-level finish on the heat sink surface, reducing the thermal resistance of the thermal contact interface and improving heat dissipation.

5.High adhesion and stability

We use advanced pre-treatment process to ensure that the nickel-gold layer is firmly bonded to the substrate, avoiding peeling or shedding during use, and ensuring stable performance for a long period of time.

Our nickel-gold plating process not only meets the high standard requirements for heatsink of semiconductor lasers, but also performs well in a variety of harsh operating environments, ensuring the efficient operation and reliability of the equipment.

In the field of high-precision processing of macro-channel,mirco-channel heatsink and heat transfer heatsink, we have been at the forefront of the industry by virtue of our exquisite processing technology and professional plating capability. Whether it is in terms of ultra-high precision, mirror-grade surfaces, perfect processing of critical edges, or high-quality plating coatings, we are able to meet the stringent requirements of our customers and provide the best solutions for all kinds of high-end applications.

Contact: Luoxu

Phone: +86-13438285256

E-mail: Sales@mightools.com

Whatsapp:+86-13438285256

Add: 7F,No.2,Tongfu Alley,Xiyulong ST.,Chengdu 610015,China

We chat