Advanced processing technologies- Additive Manufacturing

Forwarded from zhihu:https://zhuanlan.zhihu.com/p/529887744

Advanced manufacturing technology is an important cornerstone to support the fourth global industrial revolution. At present, China is making great efforts to promote the strategic arrangement to realize socialist modernization by 2035. It is the strategic goal of socialist modernization to enter the forefront of innovative countries. Breakthroughs in key core technologies are the key to entering Accelerating the development of advanced manufacturing technology is an important action for tackling key core technology problems.

Advanced metal material manufacturing and processing technology is an important direction of today's industrial development. Although our country's advanced metal material manufacturing and processing technology has achieved certain results, it still needs technological innovation. For today's social industrialization environment, advanced metal material preparation and processing,The application prospect of the technology is broad, and the processing quality and product quality can be greatly improved. It is a prerequisite for establishing a brand, and it will greatly promote the transformation from Made in China to Smart Manufacturing in China.

Now we focuses on one advanced metal material fabrication and processing technologies which have developed rapidly in recent years, additive manufacturing technology.

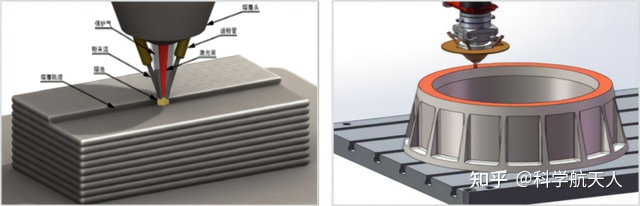

Additive manufacturing is a technology that integrates computer design, material processing and forming technology, and then uses special materials to solidify digital model files layer by layer through software and numerical control system to manufacture physical products. In other words, as long as there is an idea, data files and corresponding materials, the direct transformation from idea to entity can be realized.

The production cycle of additive manufacturing technology is short. Compared with traditional metal material preparation methods, additive manufacturing has lower requirements on the required manufacturing capacity. It requires fewer operations and easy to operate. Moreover, additive manufacturing technology occupies a small area. It’s easy to carry and can also play a role in some specific occasions. At the same time, additive manufacturing technology can perfectly reproduce the production model on 3D software, complete precise manufacturing, and realize complex structures that cannot be completed by traditional molding methods, and there is no waste after manufacturing, which improves the utilization rate of materials.

Due to the technical characteristics of additive manufacturing, it has received widespread attention from all over the world, and it will likely bring a series of profound changes to traditional manufacturing. In the past few years, the manufacturing of aviation equipment parts and the manufacturing of medical devices have always been the application places with the highest growth rate of additive manufacturing products. Global additive manufacturing revenue has reached US$15.8 billion in 2020, and is forecast to climb to US$23.9 billion in 2022 and US$35.6 billion in 2024. Additive processing and manufacturing technology is still in a period of rapid development and has strong market vitality.

However, additive manufacturing technology has relatively high requirements on raw materials, and the cost of raw materials is high. At the same time, the equipment for additive manufacturing is relatively expensive, and some key components still rely on imports, which limits the application of this technology to ordinary products. Developing low-cost raw materials and mastering key technologies to reduce equipment costs are important issues to be solved in the promotion of additive manufacturing technology.

With more appearing of new materials, difficult-to-machining materials, difficult-to-machining structures and surfaces,more requirements needed in process,the combination of new manufacturing technology as ultrasonic machining and tradational manufacturing technology as EDM, electrolytic machining, #Cutting#, #grinding# will improve machining efficiency and quality together in a broader applications.

Contact: Luoxu

Phone: +86-13438285256

E-mail: Sales@mightools.com

Whatsapp:+86-13438285256

Add: 7F,No.2,Tongfu Alley,Xiyulong ST.,Chengdu 610015,China

We chat